The requirements of providing a delta v of 600m/s, containing a 1U payload of 1.33kg, and to not exceed an acceleration of 3g have been satisfied. Some of the highlights of this illustrious and ongoing journey are explored in this paper.Ī compact hydrazine/hydrogen peroxide pressure-fed bi-propellant propulsion system for long term linear 4U CubeSat missions has been designed. From energetic propellants to green fuels, from innovative metallic alloys to ceramic composites, from seals and bearings to igniters and injectors, and from upper stages and satellites to launch vehicles and planetary landers, the dedicated and creative people at the GRC have propelled the United States to the forefront of space exploration and continue to work toward an even more exciting future. In the 60 years since this first foray into chemical propulsion, engineers at the GRC have made countless innovations and contributions to every component of rocket engine technology. Starting before the launch of Sputnik set off the great space race, researchers at the GRC were testing and flying cryogenic hydrogen-fueled engines that were an eventual key to the success of the Apollo manned missions to the moon. A decade later, it seemed only natural that these same aeropro-pulsion engineers would progress into the largely unexplored field of space chemical propulsion. The National Aeronautics and Space Administration (NASA) Glenn Research Center (GRC) was built during World War II with the primary objective of catching up with the Germans in jet engine technology. In this paper the injector is modeled using the CERO and three dimensional analyses to be carried out using ANSYS for different cases.

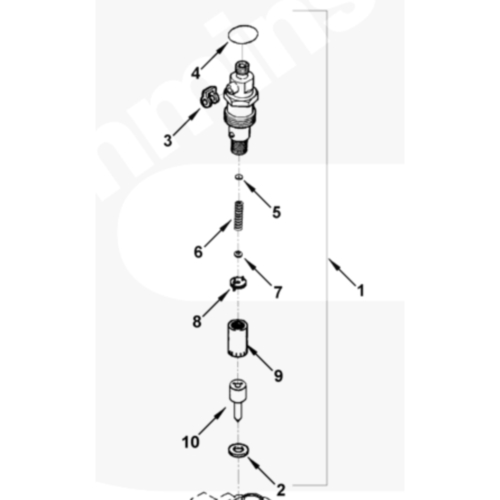

By using this principle, the liquid propellant is injected into the rocket engine for the combustion process. The principle of piezoelectric injector is defined to converting the applied mechanical energy into electrical energy. The injector implementation in liquid rocket determines the percentage of theoretical performances of the nozzle that can be achieved.

Because a poor injector performance causes unborn propellant to leave the engine, giving extremely very low efficiency. In this research, we are going to implement piezoelectric injectors for the rocket engines. If you choose to purchase new injectors, XDP will provide you with a core credit on your next replacement injector or injector set.For the past years a combined piezoelectric injector and fuel suitable for high pressure direct injection of particular small light weight aircraft. If you choose for your injectors to be returned, XDP will ship your injectors back to you ($9.95 flat rate shipping).

#PIEZO INJECTOR CONVERSION LB7 PDF#

You will then receive an email with a PDF of test results. Q: What do I get?A: With the XDP Injector Testing Service your injectors will be tested on a Bosch EPS 205 Test Stand. XDP recommends a trackable and insured method for your protection. Q: What if I don't insure my shipment?A: You can send your injectors to XDP using any method you would like.

Click here to view proper packing procedure. In addition, some injectors such as Ford 6.7L, or Duramax LML have return line fittings that can be extremely fragile and once broken, render the injector useless. Ensure that they are clean and bagged to eliminate the risk of leak-through damaging a box. Protect your injectors in a well fitting box with proper packaging material. Q: How do I properly pack my injectors?A: Fuel injection components can be the most expensive part of a diesel engine. It will not be necessary to decode all of the technical information that will be provided. Q: How do I read test results?A: The test results will include a pass or fail diagnosis.

0 kommentar(er)

0 kommentar(er)